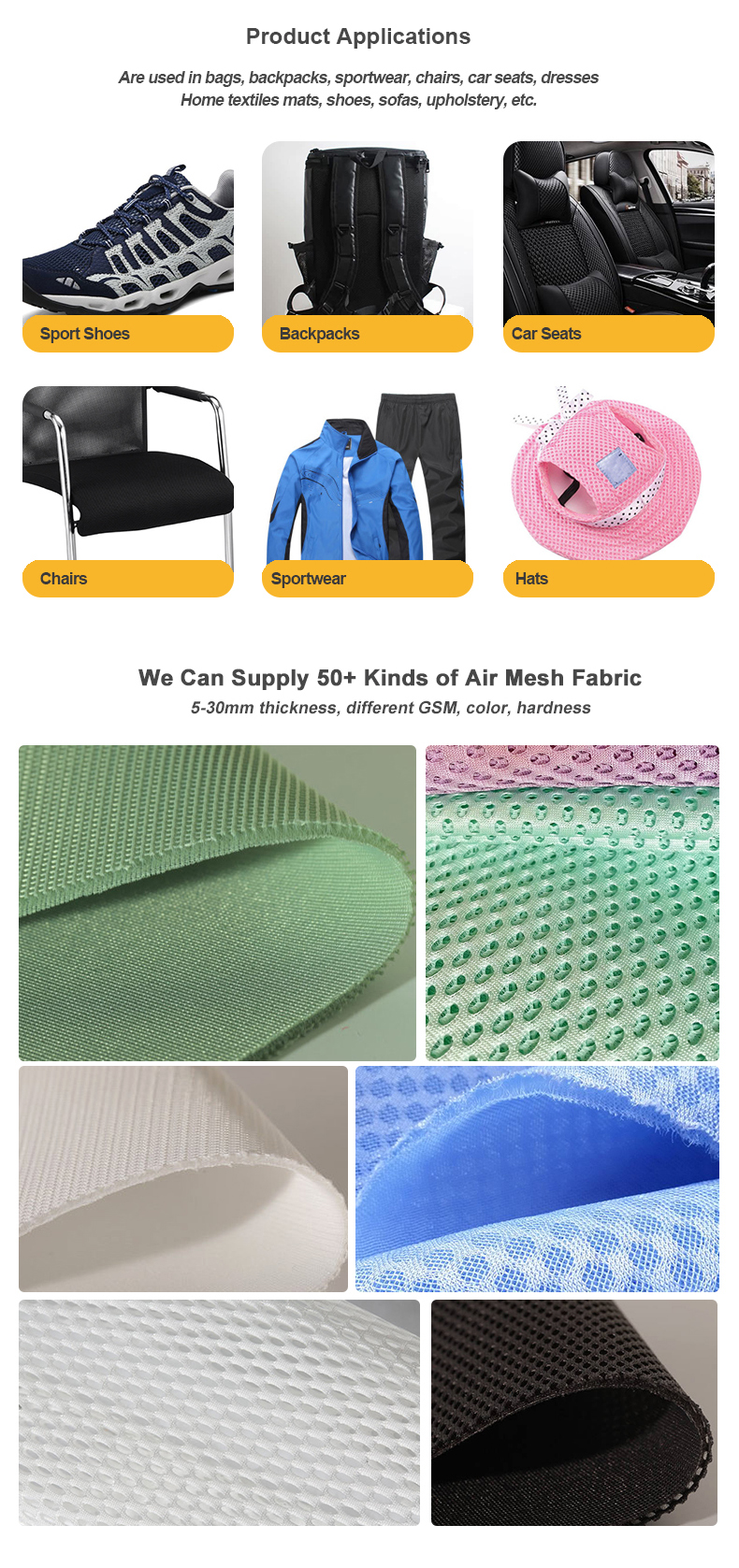

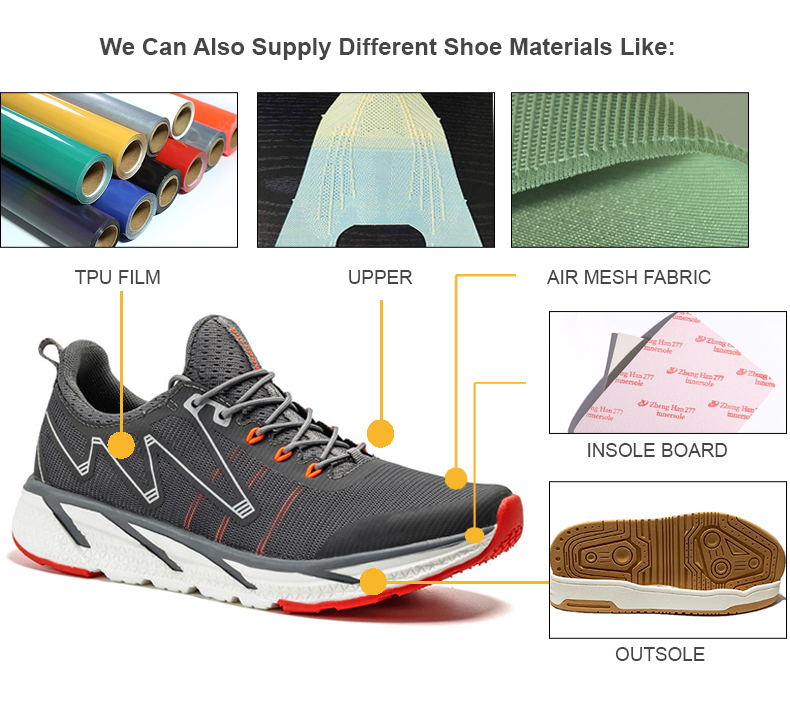

Sport Mesh Fabric: Spot Polyester Warp Knitting Mesh for Sportswear Lining, Bags, Hats, and Shoes

- Lightweight and Breathable: Ensures maximum airflow, keeping you cool and comfortable during intense physical activities.

- Durable and Abrasion-Resistant: Built to withstand rigorous use, providing long-lasting performance for sportswear and gear.

- Flexible and Supportive: Offers excellent stretch and support, allowing for freedom of movement without sacrificing fit or comfort.

How Is Mesh Fabric Made?

Mesh fabric production involves various techniques that depend on the type of fiber used, such as nylon or polyester. Although similar in many respects, polyester’s development occurred later than nylon’s, allowing for more advanced manufacturing processes in its production.

The process begins with refining petroleum oil to extract polyamide monomers. These monomers are then reacted with different forms of acid to create polymers. Initially, these polymers are solid, but they are melted and forced through spinnerets, which shape them into fine strands.

After cooling, these strands are wound onto spools and sent to textile manufacturing facilities for mesh fabric production. Typically, manufacturers dye the polyester or nylon fibers before weaving them into fabric.

Textile manufacturers use various weaving techniques to create different mesh forms. Many types of mesh follow a traditional square pattern that has been effective for centuries. However, contemporary styles, such as Tulle, may feature a hexagonal weave, adding to the versatility and aesthetic appeal of the fabric.

| Product Type | mesh fabric |

| Width | 1.4M,1.5M,1.6M |

| Weight | 50gsm-180gsm |

| Material | 100% polyester |

| Color | Various colors can be customized |

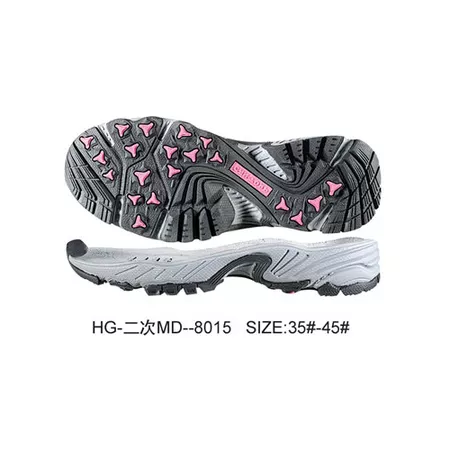

| Application | for bedding,sports shoes,bags,chairs,home Textile,tent,sofa |

| MOQ | 1000m/color & 5000m/order |

| Feature |

Soft, Breathable, Eco friendly, Recyclable Upper Material

|

| Package |

in rolls or according to customer’s requirement

|